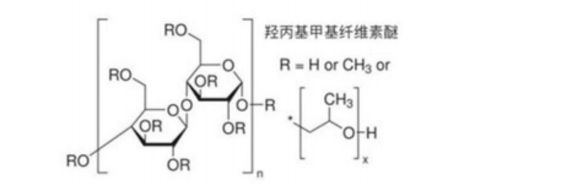

constraction grade Hydroxypropyl Methyl Cellulose HPMC For Drymix Mortar

Specification

| item | value |

| Classification | Chemical Auxiliary Agent |

| CAS No. | 9004-65-3 |

| Other Names | HEMC |

| MF | C12H20O10 |

| EINECS No. | 220-971-6 |

| Purity | 99.99 |

| Place of Origin | China |

| Hebei | |

| Type | Adsorbent |

| Activated Carbon | |

| Usage | Coating Auxiliary Agents, Electronics Chemicals, Leather Auxiliary Agents, Paper Chemicals, Petroleum Additives, Plastic Auxiliary Agents, Rubber Auxiliary Agents, Surfactants, Textile Auxiliary Agents, Water Treatment Chemicals |

| Brand Name | Yulan |

| Product name | High |

| Application | Construction |

| Appearance | White Powder |

| Color | White Color |

| Material | Refined Cotton |

| Package | 25kg/bag |

| MOQ | 1000 KG |

| PH | 6-8 |

| Sample | Freely Provided |

| Viscosity | 100000-200000 |

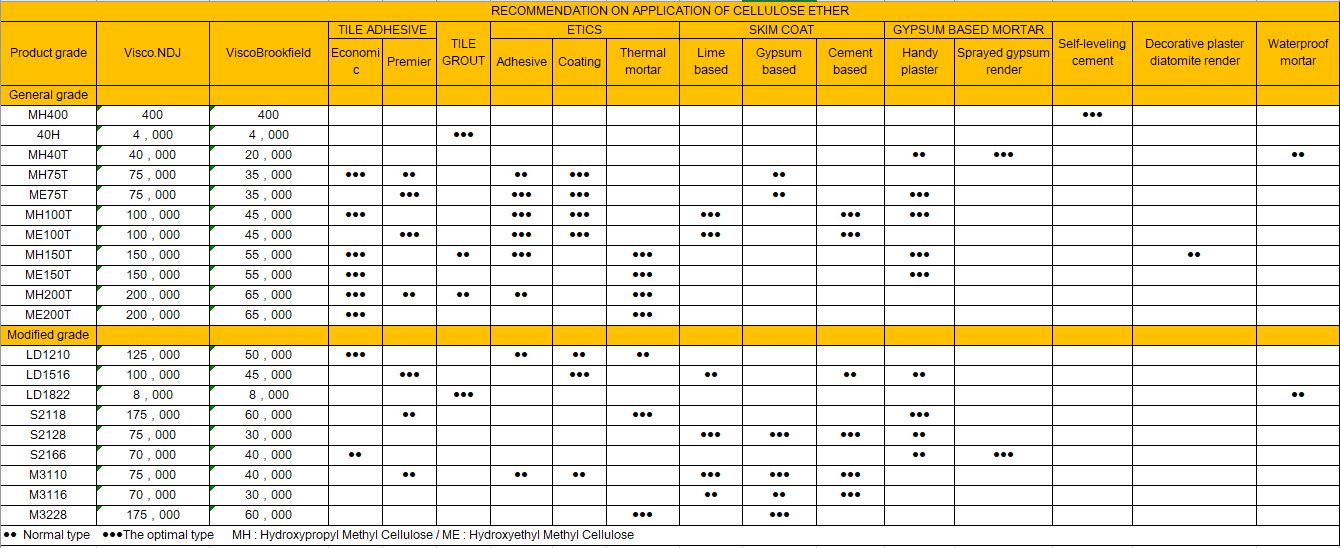

Product Viscosity

Construction-grade crystalline cellulose for mortar (here refers to pure cellulose, excluding existing products) in terms of viscosity range

Generally, the following types are commonly used (the unit is viscosity)

Low viscosity: 400 is mainly used for self-leveling mortar, but it is generally imported.

Reason: The viscosity is low, although the water retention is poor, but the leveling property is good, and the mortar density is high.

Medium and low viscosity: 20000-40000 is mainly used for anti-cracking mortar, thermal insulation cement mortar, etc.

Reason: good construction, less water, high density of mortar.

Medium viscosity: 75000-100000 mainly used for putty

Reason: good water retention

High viscosity: 150000-200000 Mainly used for tile adhesive, caulking, polystyrene particle insulation agent, mortar glue powder and vitrified microspheres Insulation mortar.

Reason: high viscosity, mortar is not easy to fall off, sagging, which improves the construction.

But generally speaking, the higher the viscosity, the better the water retention. Therefore, considering the cost, many dry powder mortar factories use medium

Viscosity cellulose (75000-100000) replaces medium and low viscosity cellulose (20000-40000) to reduce the amount added.

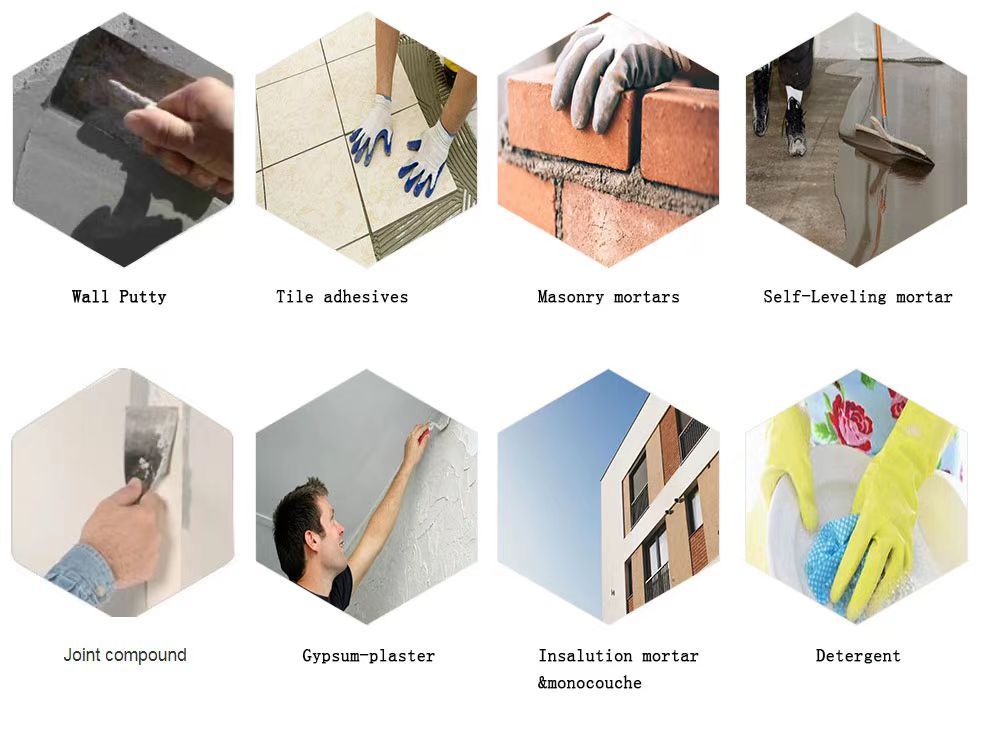

Application

Construstion: tile adhesives, wall putty/skim coat, plaster/render mortars, EIFS, tile grouts, joint filler, self leveling compounds, detergents,water based paints and coatings, etc.

Homecare prodcuts: shampoo, detergent, etc.

PVC/PEC: plastic forming mold release agent, softener, lubricants

Paints and Ink: thickening agent, dispersing agent and stabilizer

Package Details

● Sample packaging

500g sample in airtight plastic bag and then packed in a sealed aluminium foil bag

● Packaging for products over 1 tonne

25kg /paper bags with PE inner. Cellulose ethers (HPMC, HEMC): 20'FCL:10 tons with pallets or 12 tons without pallets. 40'FCL:20 tons with pallets or 24 tons without pallets.

Company Profile