Hydroxy Propyl Methyl Cellulose Powder Industrial Chemicals HPMC for Ceramic Glue

Daily chemical grade HPMC advantages

HPMC chemical has good compatibility with various additives of other daily chemical products. It is widely used in detergents, shower gels, shampoos, hand sanitizers, and laundry liquid and other products.

• Non-toxic, non-irritant, and non-allergenic

• Water-soluble and highly soluble in organic solvents

• Compatible with a wide range of other chemicals

• Offers excellent film-forming properties

• Provides excellent viscosity control and thickening ability

Other related products include

Construction Grade HPMC

Gypsum Special Grade HPMC

VAE/RDP

Daily chemical grade HPMC application

HPMC provides excellent thickening and foam stabilization properties, improving the overall texture and consistency of hair care products. The daily chemical grade cellulose ether from Yulan is suitable for shampoo, detergent, conditioner, styling products, toy bubble water etc.

If you are looking for high quality daily chemical grade HPMC for sale, welcome to contact us!

Daily chemical grade hydroxypropyl methylcellulose HPMC effect

In detergent applications, the HPMC powder is mainly used for thickening, foaming, stable emulsification, dispersion, adhesion, film formation and water retention of detergents. High viscosity products are used for thickening, and low viscosity products are mainly used for suspension dispersion and film formation.

Product viscosity

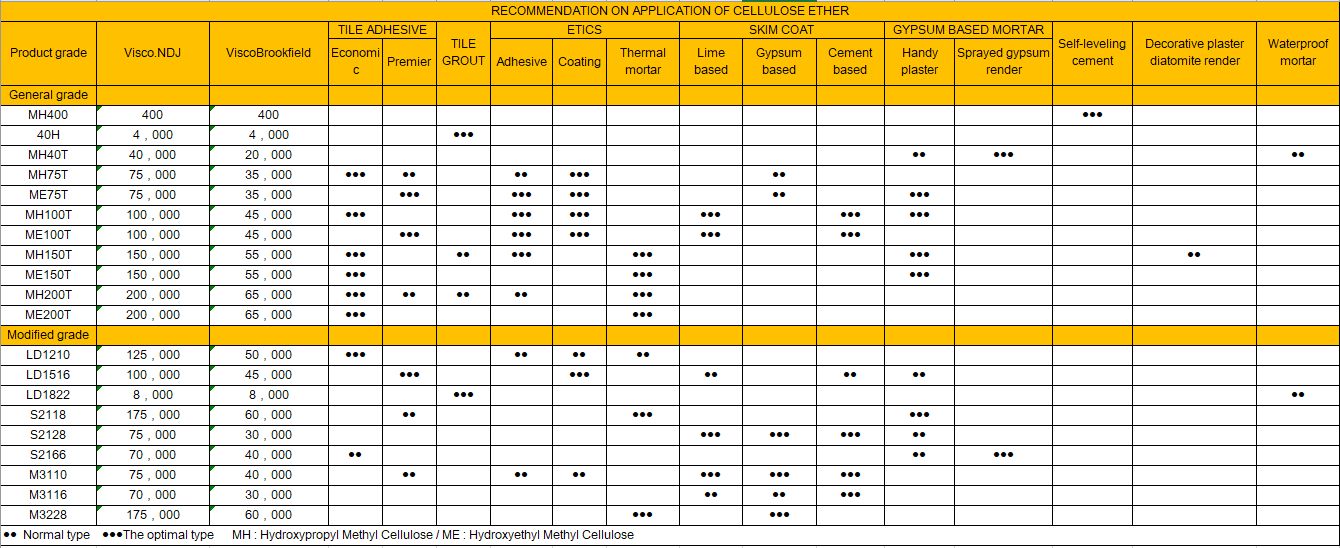

Construction-grade crystalline cellulose for mortar (here refers to pure cellulose, excluding existing products) in terms of viscosity range

Generally, the following types are commonly used (the unit is viscosity)

Low viscosity: 400 is mainly used for self-leveling mortar, but it is generally imported.

Reason: The viscosity is low, although the water retention is poor, but the leveling property is good, and the mortar density is high.

Medium and low viscosity: 20000-40000 is mainly used for anti-cracking mortar, thermal insulation cement mortar, etc.

Reason: good construction, less water, high density of mortar.

Medium viscosity: 75000-100000 mainly used for putty

Reason: good water retention

High viscosity: 150000-200000 Mainly used for tile adhesive, caulking, polystyrene particle insulation agent, mortar glue powder and vitrified microspheres

Insulation mortar.

Reason: high viscosity, mortar is not easy to fall off, sagging, which improves the construction.

But generally speaking, the higher the viscosity, the better the water retention. Therefore, considering the cost, many dry powder mortar factories use medium

Viscosity cellulose (75000-100000) replaces medium and low viscosity cellulose (20000-40000) to reduce the amount added.

Package Details

● Sample packaging

500g sample in airtight plastic bag and then packed in a sealed aluminium foil bag

● Packaging for products over 1 tonne

25kg /paper bags with PE inner. Cellulose ethers (HPMC, HEMC): 20'FCL:10 tons with pallets or 12 tons without pallets. 40'FCL:20 tons with pallets or 24 tons without pallets.

Company Profile