Chemical Additive HPMC Hydroxypropyl Methyl Cellulose for Ceramic Tile Binder

Product Description

Hydroxypropyl MethylCellulose (HPMC) are widely used in construction, pharmaceutical,food, cosmetic, detergent, paints, as thickener, emulsifier, film-former, binder, dispersing agent, protective colloids.We can provide the regular grade HPMC, we also can provide modified HPMC according to customer requirements. After modified and surface treatment, we can get the goods which is dispersed in water quickly, lengthen open time, antisagging, etc.

Product Parameters

| Appearance | White or off-white powder |

| Methoxy ( % ) | 19.0~ 24.0 |

| Hydroxypropoxy ( % ) | 4.0 ~ 12.0 |

| pH | 5.0~ 7.5 |

| Moisture ( % ) | ≤ 5.0 |

| Residue on ignition ( % ) | ≤ 5.0 |

| Gelling temperature ( ºC ) | 70~ 90 |

| Particle size | min.99% pass through 100 mesh |

Typical Applications of HPMC:

Tile Adhesive

Good water retention: prolonged opening time will make tiling more efficient.

Improved adhesion and sliding resistance: especially for heavy tiles.

Better workability: lubricity and plasticity of plaster is ensured, mortar can be applied easier and quicker.

Cement Plaster / Dry mix mortar

Easy dry mix formula due to cold water solubility: lump formation can be easily avoided, ideal for heavy tiles.

Good water retention: prevention of fluid loss to the substrates, the appropriate water content is kept in mixture which guarantees longer concreting time.

Increased water demand: increased open time, expanded spry area and more economical formulation.

Easier spreading and improved sagging resistance due to improved consistency.

Wall putty

Water retention: maximized water content in slurry.

Anti-sagging: when spreading a thicker coat corrugation can be avoided.

Increased mortar yield: depending on the weight of the dry mixture and appropriate formulation ,HPMC can increase the mortar volume.

Exterior Insulation and Finish System ( EIFS )

Improved adhesion.

Good wetting ability for EPS board and substrate.

Reduced air entrancement and water uptake.

Self-leveling

Protection from water exudation and material sedimentation.

No effect on slurry fluidity with low viscosity HPMC, while its water retention characteristics improve the finish performance on the surface.

Crack Filler

Better workability: proper thickness and plasticity.

Water retention ensures prolonged work time.

Sag resistance: improved mortar bonding ability.

Application

1. Cement mortar: Improve the dispersion of cement-sand, greatly improve the plasticity and water retention of the mortar, and have an effect on preventing cracks, which can enhance the strength of the cement.

2, tile cement: improve the plasticity, water retention of the pressed tile mortar, improve the bonding strength of the tile, prevent powdering.

3, asbestos and other refractory coating: as a suspension agent, fluidity improver, but also improve the adhesion to the substrate.

4, gypsum coagulation slurry: improve water retention and processability, improve the adhesion to the substrate.

5. Joint cement: added to the joint cement for gypsum board to improve fluidity and water retention.

6. Latex putty: Improve the fluidity and water retention of putty based on resin latex.

7. Stucco: As a paste instead of natural material, it can improve water retention and improve the bonding force with the substrate.

8. Coating: As a plasticizer for latex paint, it has an effect on improving the handling properties and fluidity of paints and putty powder.

9. Spray coating: It has good effect on preventing the cement or latex coating from sinking and improving the fluidity and spray pattern.

10. Cement and gypsum secondary products: used as an extrusion molding binder for hydraulic materials such as cement-asbestos, which improves fluidity and provides uniform molded articles.

11. Fiber wall: It is effective as a binder for sand walls due to its anti-enzyme and antibacterial action.

12. Others: It can be used as a bubble retaining agent (PC version) which acts as a thin clay mortar and a mud hydraulic operator.

Package details

Sample packaging

500g sample in airtight plastic bag and then packed in a sealed aluminium foil bag

Packaging for products over 1 tonne

25kg /paper bags with PE inner. Cellulose ethers (HPMC, HEMC): 20'FCL:10 tons with pallets or 12 tons without pallets. 40'FCL:20 tons with pallets or 24 tons without pallets.

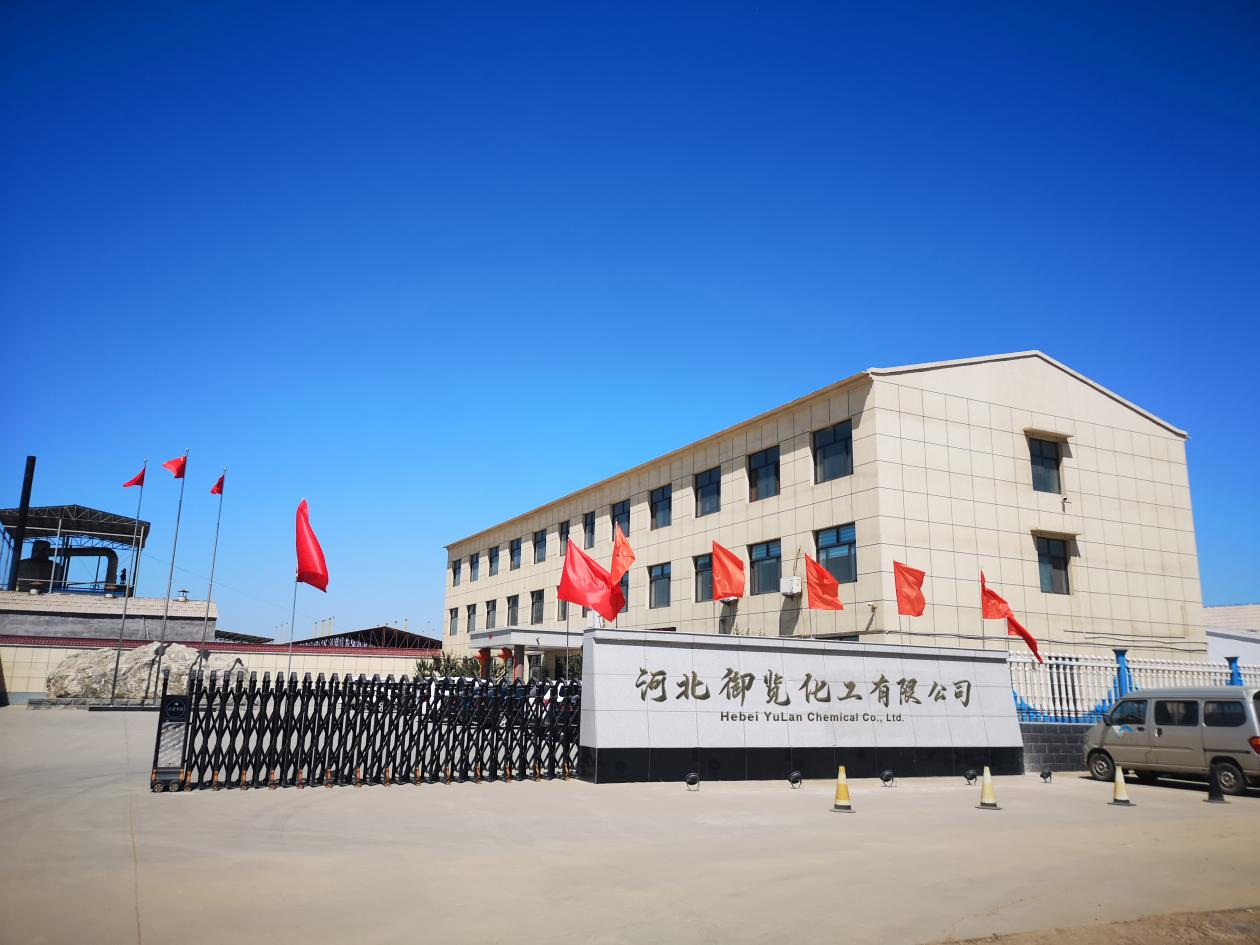

Company profile

Hebei YuLan Chemical Co., Ltd is a large-scale processional manufacturer of fine chemical cellulose ether. The plant is located in the provincial clean chemical park of Xinji County, Shijiazhuang City,with the complete environmental protection procedures, is the key cultivation enterprise of Xinji County. The factory covers an area of 500,000 square meters, fixed asset of 150 millions USD, 400 employees and 42 senior technicians. The factory adopts 8 advanced production technology and equipment lines from Germany, with a product quality rate of 100%, daily output can be up to 300 tons at now.

After more than 10 years of unremitting efforts and continuous development, the factory has become to the largest manufacturer of cellulose ether and the only one with 75 degree gel temperature technology in Hebei Province.The factory products have achieved a good reputation at home and abroad with excellent quality and excellent service. It has been exported to more than 20 countries and regions, and has been praised and trusted by users at home and abroad.

Hydroxy Propyl Methyl Cellulose is the leading products of the factory, widely used in the fields of chemical industry, construction, building materials, coatings, food, cosmetics,agriculture,national defense and military industry,etc. The factory has passed the ISO9001-2000 international quality system certification, and the products quality has reached international advanced level,and the variety and quality meet the requirements of domestic and foreign customers.

The factory strong economic strength and abundant human resources have laid a solid foundation for its long-term development. Excellent quality, better price and considerate service are our factory's goal. We are willing to cooperate with domestic and abroad customers, keep pace with the times and create brilliant future together!

Factory show

At the beginning of 2018, for adopting the requirements of market , we invested 20 millions USD on the phase-Ⅲ production line. In 2021, the yearly output reaches 40,000 metric tons. Landcel has successfully passed ISO 9001 and made REACH registration in 2021.

LANDCEL always abide by "Quality first, Customer first" to develop sustainable and win-win relationships with our clients and benefit our partners with long terms.